For air pollution control and possible innovation incentives lower emission values are demanded. After years of intense work in our R&D department and a Europe-wide field test ÖkoFEN has succeeded in taking a big step towards absolutely clean energy conversion from wood pellets.

WHY DID WE DEVELOP ZEROFLAME®?

The aim was to develop a solution that would bring absolutely no restrictions to the previous technology in terms of comfort and reliability. Alternatively, electric high-voltage particle filters are used in the industry, but they are cost-intensive and rarely maintenance-free. So this option was soon discarded. As a result we continued to work on a better, simpler solution, which takes place directly in the combustion chamber.

HOW DOES ZEROFLAME® WORK?

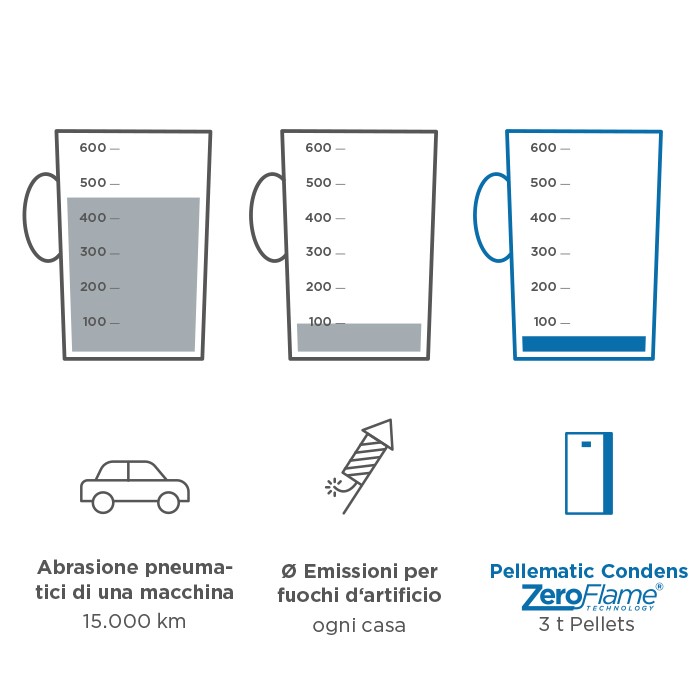

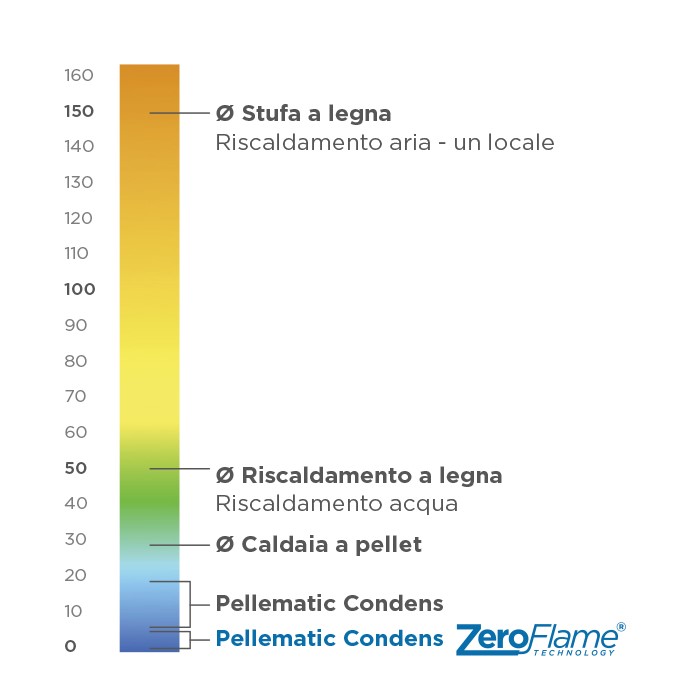

ZeroFlame® is a milestone in ÖkoFEN history. The special-guided airflow and air-enrichment in combination with a special combustion chamber design leads to a very special effect. The flame disappears almost completely during combustion and reduces particulate matter to a minimum. All that remains is: Cosy warmth and clean exhaust air!

THE CLEANEST ÖKOFEN PELLET BOILER EVER

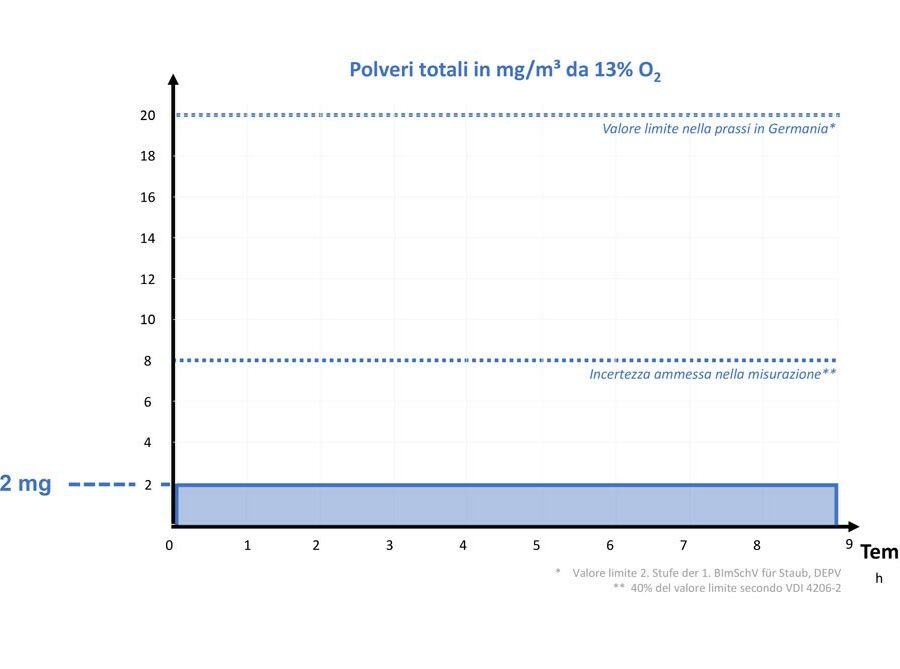

TESTED BY TÜV AUSTRIA

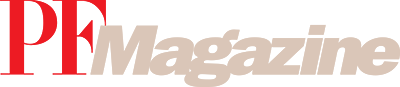

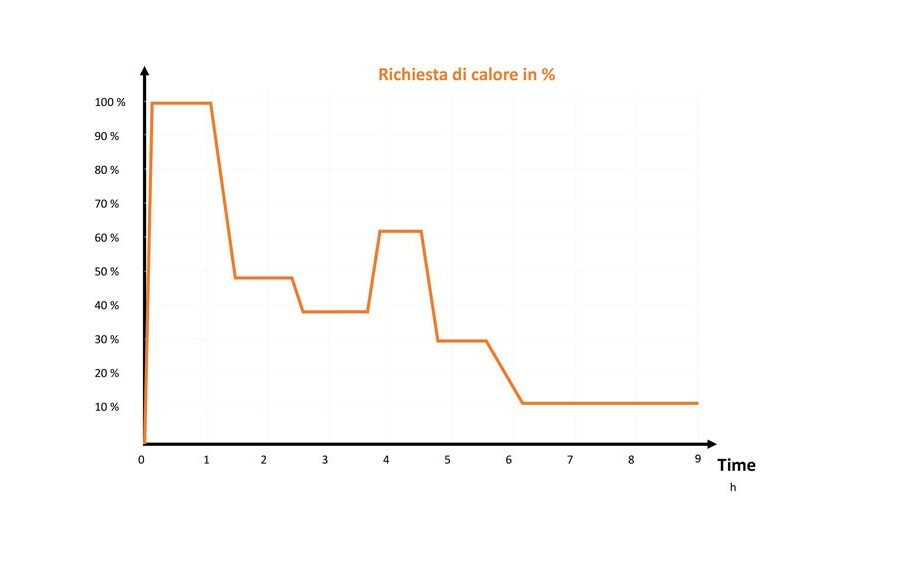

The amount of particulate matter leaving the high-efficient pellet heating system can hardly be measured. This has a high impact to the environmental situation worldwide. A practice 9-hour load cycle test carried out by TÜV Austria officially confirms the excellent values and unique effect of the new technology.